Pioneer in Diesel and Gas Engine Production

Cummins Inc., renowned globally as a trailblazer in the manufacturing of diesel engines for trucks traversing long distances, has its roots in modest beginnings. Its foundation was laid by Clessie Cummins, an Indiana native born in 1888, whose formal education didn’t progress beyond the eighth grade, compelling him to abandon school to assist with work on the family’s agricultural land.

Despite his limited formal education, Clessie demonstrated a remarkable affinity for mechanics from a young age. As legend has it, he engineered his own steam engine at the tender age of 11 using molten iron, which he cast into wooden molds. This invention went on to become a pivotal irrigation tool on his family’s farm.

An Innate Engineer

Clessie’s mechanical prowess and innovative mindset, akin to those of an engineer, facilitated his role as a mechanic at Marmon Motor Company. This position paved the way for his collaboration with Ray Harroun on the groundbreaking Marmon Wasp race car, which clinched victory at the inaugural Indy 500 in 1911. Clessie was a pit crew member for this winning car.

In parallel, Clessie also served as a chauffeur for William Irwin, a banker and investor from Columbus, Indiana, who was a substantial supporter of Harroun’s endeavors. Irwin quickly recognized Clessie’s extraordinary capabilities and encouraged him to explore engine construction for local agriculture.

Birth of Cummins Engine Company

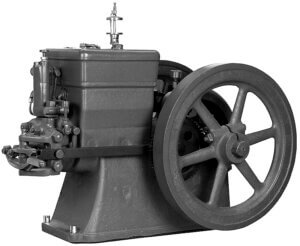

In 1918, upon encountering a diesel engine imported from the Dutch company R.M. Hvid, the founders saw a significant opportunity to manufacture this innovative engine type for the American market under a licensing agreement. The Cummins Engine Company was officially founded in Columbus, Indiana, in 1919. It quickly began producing modified versions of the Hvid diesel engines, incorporating improvements by Clessie, with power outputs ranging from 1.5 to 8 horsepower (1.1 to 6 kW) at 600 revolutions per minute. Approximately 3,000 units were manufactured. By 1921, Cummins had successfully obtained patents for two out of 33 proposals, focusing on enhancing fuel efficiency and advancing manifold technology for the Hvid engines they were licensed to produce.

Being the innovator he was, Cummins wasted no time in enhancing the Hvid engine, with some of his modifications earning patents. The experience and rights acquired through the Hvid license paved the way for Cummins’ creation of their own engine, the Model M (featuring a 5-inch bore, 7.5-inch stroke, and 7.5 hp per cylinder) available in one to four cylinders. This was soon followed by the Model F (with a 5.5-inch bore and 7-inch stroke), introduced in 1924. The launch of the Model F marked the end of the partnership with Hvid, with Irwin continuing to provide financial support.

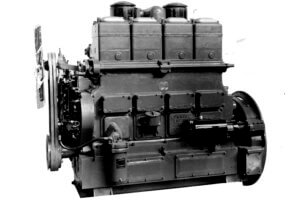

Following these developments, Cummins introduced diesel engines such as the Model K, KO, and L/LR/LRT, many of which served the marine and industrial sectors for four decades. In 1929, they also introduced the single-disc fuel system, a pioneering technology that created fuel pressure directly within the injector. This system remained in use throughout World War II.

But it was the four-cylinder, fuel injected, two-stroke design in the Model H engine, that became the first commercially available engine for heavy-duty trucks. The success of this innovative design propelled the company’s success into the decades that followed.

Expansion into Marine and Diesel Sectors

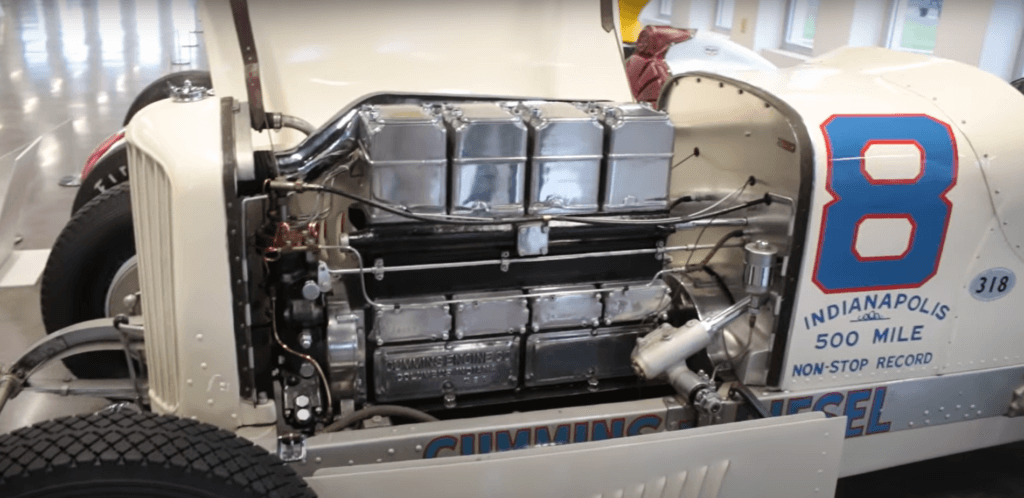

Cummins continued to expand its footprint, supplying engines to marine and industrial sectors for four decades and making significant strides in engine development. Cummins was appointed as the president of the company in 1930 and played a pivotal role in promoting diesel engines through sponsorship of race cars, including the pioneering turbocharged engine featured in the Indy 500.

Cummins continued to expand its footprint, supplying engines to marine and industrial sectors for four decades and making significant strides in engine development. Clessie Cummins was appointed as the president of the company in 1930 and played a pivotal role in promoting diesel engines through sponsorship of race cars, including the pioneering turbocharged engine featured in the Indy 500.

During the 1950s, the trucking industry began to experience significant growth. It was in the midst of this decade that Cummins launched the NH220 engine, a naturally aspirated 6-cylinder diesel engine with a displacement of 743 cubic inches, capable of producing 220 horsepower—a remarkable figure for the time. By 1957, the N series engine had been enhanced to 855 cubic inches, with turbochargers and aftercoolers introduced in subsequent years. The 855/N series engine block, despite numerous updates, continues to be produced today in its fundamental form as the Cummins N14.

Following Clessie’s separation from the company in 1954, J. Irwin Miller, William Irwin’s grandnephew, assumed leadership roles, under whose stewardship Cummins Inc. fortified its market presence, powering approximately 60% of U.S. diesel trucks by 1955. Clessie lived to see his company achieve international success before passing away in 1968.

Under Miller’s leadership, Cummins recognized the benefits of producing internationally. In 1956, they established their first factory abroad in Shotts, Scotland. By the late 1960s, Cummins had expanded its reach, boasting a network of over 2,500 dealers across 98 countries. This era also marked a return to the company’s origins with the development of newer, smaller industrial engines.

Diversification and Innovation in Natural Gas Engines

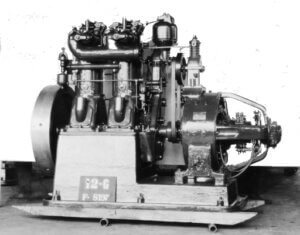

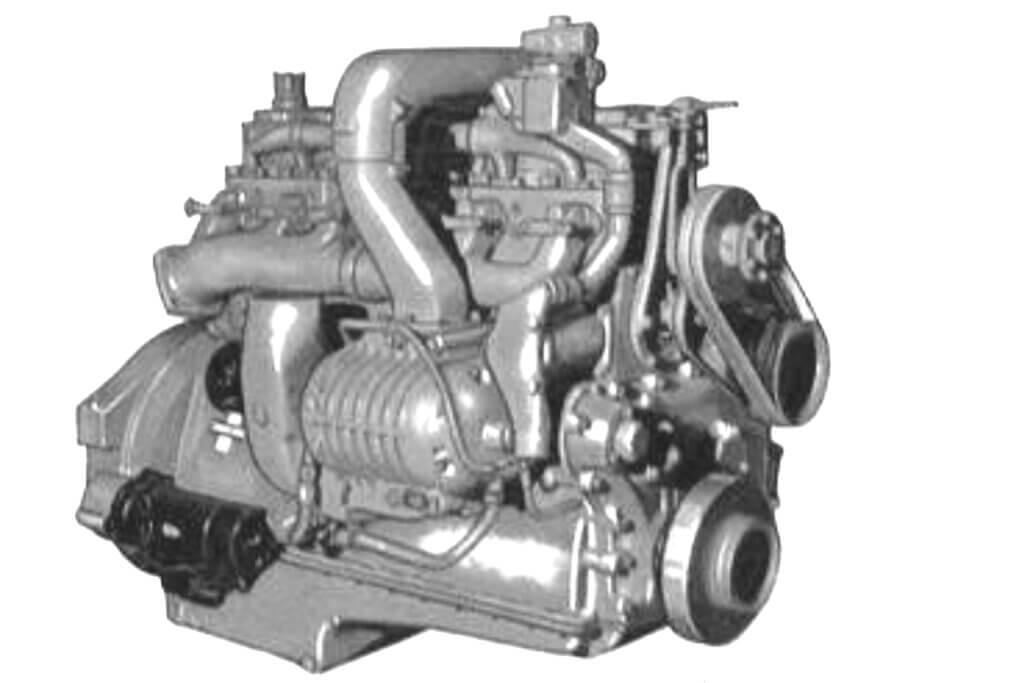

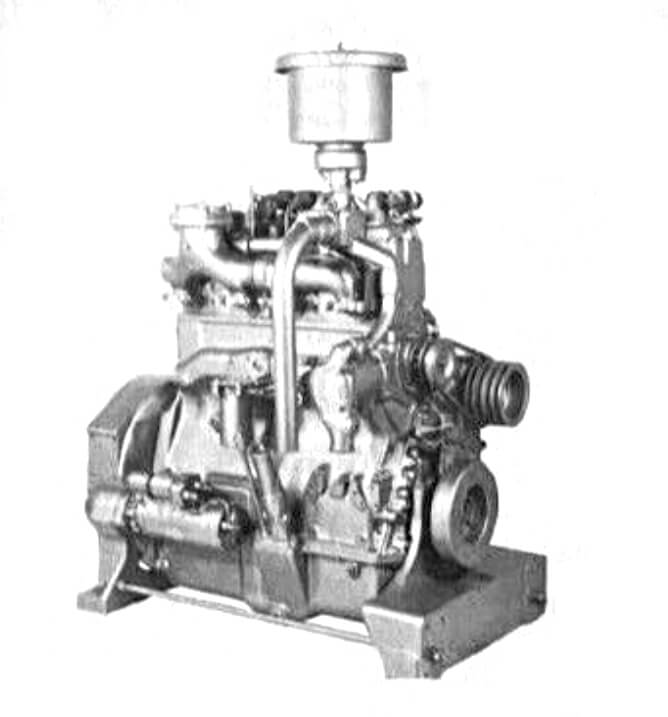

Facing market pressures and heightened competition in the early 1960s, Cummins Inc. diversified its portfolio in 1964, venturing into the production of natural gas engines, with many serving reliably for five decades in various applications, including power generation and compressor drives. Pictured here is the 109 hp (81 kW), 1800 rpm model G-495. It is an early example of a mechanical drive application for the emerging gas compression market.

Despite initial challenges, Cummins strengthened its position in the global diesel market and enhanced its gas engine offerings. Cummins eventually regained its lead in the global diesel market. growing to production of 1.5 million engines in 2018. The company released its first heavy-duty natural gas engine in 1991 using the same base engine components, including the blocks, crankshafts and connecting rods, used in Cummins diesel engines. The company adopted a meticulous and customer-centric approach, culminating in significant market share growth for Cummins gas engines by the late 1990s.

As of the latest data, Cummins Inc. continues to uphold its legacy of innovation and excellence, cementing its position as a global leader in engine manufacturing. The company’s focus on sustainability and commitment to developing eco-friendly solutions signify its vision for the future. Cummins is poised to navigate the challenges of a rapidly changing industry landscape, leveraging its technological prowess and extensive experience to shape the future of engine technology.

Sustained Success in Gas Compression Drive Market

Cummins has continually evolved over the past three decades, achieving commendable success in the gas compression drive market with a diverse range of models. As of 2019, the company boasted over 80,000 gas engines in operation globally, serving varied applications such as natural gas vehicles, power generation, and compressor drives.

This was achieved through decades of experience in the gas compression market. New design features reflected customer input and resulted in improved performance with delivery of more fuel tolerant 8.5:1 compression ratio. Field trials preceded large scale release of each production model. This approach was successful, and by the late 1990s, Cummins gas engines were growing market share as 1800 rpm drivers for rotary screw and reciprocating gas compressors.

When fully developed and released, Cummins’ naturally aspirated and turbocharged four-cycle natural gas engine line ranged from 41 hp to 760 hp (31 to 567 kW). In 2019, the company reported that more than 80,000 of its gas engines were in use in applications that included natural gas vehicles, power generation and compressor drives.

In the last 30 years, Cummins has succeeded in the 1800 rpm gas compressor drive market with a range of models with 8.5:1 compression ratio. Listed here are the most common models used for gas compression drive applications in the U.S.

| MODEL | BORE IN. (MM) | STROKE IN. (MM) | NO. OF CYLINDERS | RATING @ 1800 RPM HP (KW) |

| GTA5.9 | 4.02 (102) | 4.72 (120) | 6 inline | 116 (87) |

| GTA8.3 | 4.49 (114) | 5.32 (135) | 6 inline | 190 (142) |

| GTA8.3 SLB | 4.49 (114) | 5.32 (135) | 6 inline | 175 (130) |

| GTA855 | 5.50 (140) | 6.00 (152) | 6 inline | 286 (213) |

| GTA855E | 5.50 (140) | 6.00 (152) | 6 inline | 256 (191) |

| KTA19GC | 6.25 (159) | 6.25 (169) | 6 inline | 420 (313) |

| KTE38GCE | 6.25 (159) | 6.25 (159) | 12 vee | 760 (567) |

Conclusion

Cummins Inc.’s journey from a modest start to becoming a global leader in engine manufacturing exemplifies innovation, resilience, and continual development. The company’s advancements in diesel and gas engine technology have had a profound impact on multiple industries, setting high standards in engine performance and reliability.